HYDRAULIC GANTRYHydraulic Gantry

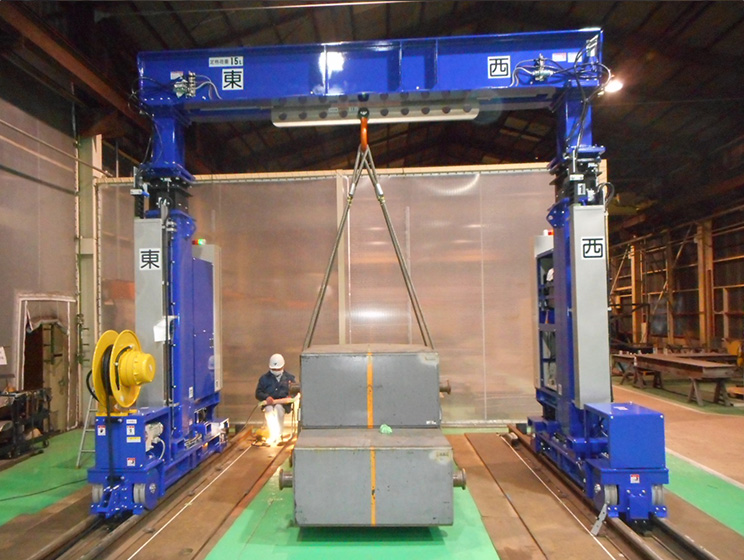

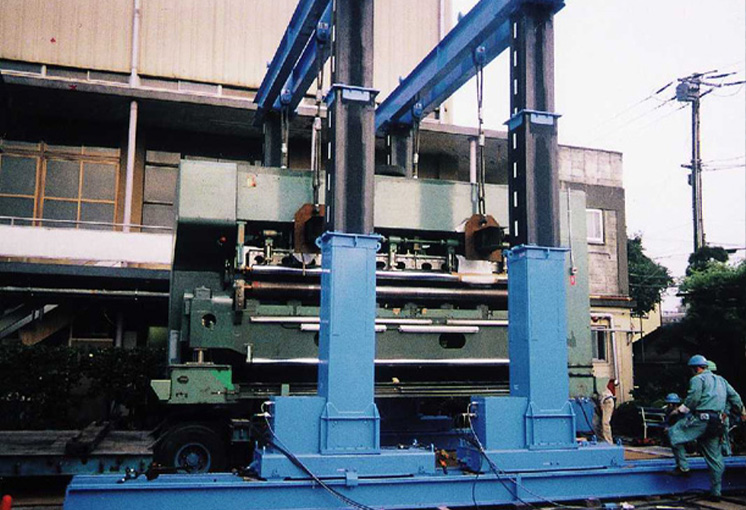

A Hydraulic Gantry is a lifting machine that uses jack mechanisms that extend and retract with hydraulic cylinders and a beam to raise a load.

Special specifications are also available to move the lifted load in the left/right (traversing) and front/back (traveling) directions by power.

- Features

- Standard Line Up

- Special Specifications/Custom Models

- Inquiry

- Customer Story

- Main Customers (in preparation)

Features

-

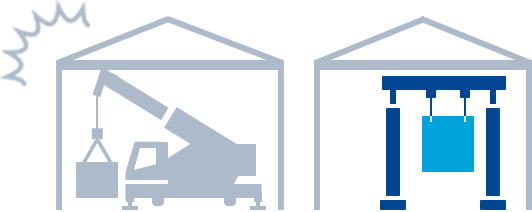

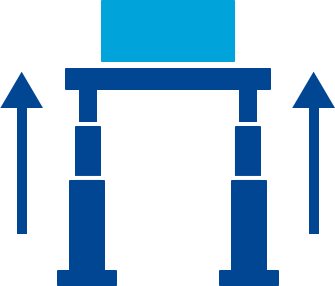

Even in places with low ceilings that make crane work difficult, you can make effective use of narrow spaces.

(Inside buildings, underground spaces, tunnels, under elevated tracks, under bridges, etc.)

-

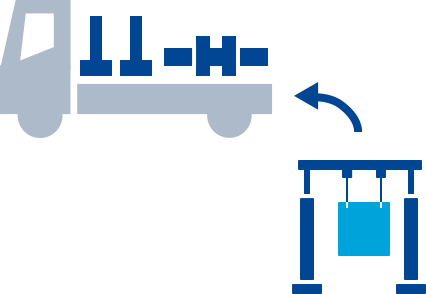

It can be disassembled and transported compactly and assembled easily on site.

-

It can also be used for pushing up a load as a jack.

-

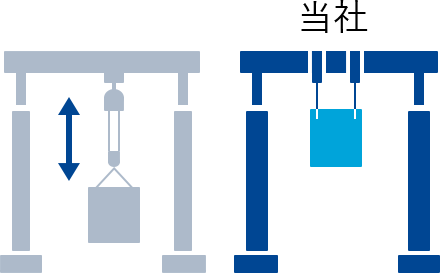

Lifting height loss is reduced because slinging can be performed directly onto a dedicated hanger without the use of a chain block.

-

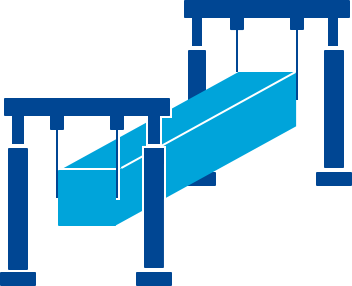

The use of multiple hydraulic gantries enables the handling of long objects.

Standard Line Up

TB-36

- Lifting capacity

- 3.6 t

- Stroke

- 1,700 mm

- Jack span

- 2,500 mm

- Price

- \4,700,000 (excluding tax)

- Delivery date

- 3.5 months

TB-50

- Lifting capacity

- 5t

- Stroke

- 1,700 mm

- Jack span

- 4,000 mm

- Price

- \7,600,000 (excluding tax)

- Delivery date

- 3.5 months

TB-100

- Lifting capacity

- 10 t

- Stroke

- 3,000 mm

- Jack span

- 5,000 mm

- Price

- \10,200,000 (excluding tax)

- Delivery date

- 5 months

TB-300

- Lifting capacity

- 30 t

- Stroke

- 3-tier jack:3-stage jack:3,500 mm4-tier jack:4-stage jack:5,070 mm

- Jack span

- 7,100 mm

- Price

- 3-tier jack:3-stage jack:\31,500,000 (excluding tax)4-tier jack:4-stage jack:\39,500,000 (excluding tax)

- Delivery date

- 12 months

TB-600

- Lifting capacity

- 60 t

- Stroke

- 3-tier jack:3-stage jack:3,500 mm4-tier jack:4-stage jack:5,070 mm

- Jack span

- 7,100 mm

- Price

- 3-tier jack:3-stage jack:\54,000,000 (excluding tax)4-tier jack:4-stage jack:\69,000,000 (excluding tax)

- Delivery date

- 12 months

- *The lifting capacity is the maximum weight that can be lifted when the center of gravity of the load is in the center between the beam fulcrums and within 1/3 of the length between the fulcrums.

- *The price is for one set of standard specifications. A set of standard specifications includes jacks, traveling frames, beams, hangers, hydraulic units, operating devices, hydraulic hoses, cables, and accessories. The driving device for traveling, the traversing device, and the traveling rails are not included. (sold separately)

- *Delivery time varies depending on inventory and order status. In addition, it may vary greatly depending on the combination of special specifications and optional products. Please feel free to contact us.

- *Please note that product design, specifications, appearance, and prices are subject to change without notice.

Special Specifications/Custom Models

Here are some examples of special specifications and custom models for gate-type hydraulic lifters.

If you think "I want to know the details of the product", "I want this kind of function", etc., please feel free to contact us.